19 Hidden Spots in Your Washing Machine That Are Breeding Toxic Mold (Check #13 ASAP!)

When Sarah discovered black spots spreading across her washing machine’s door seal, she had no idea it was just the tip of the iceberg.

You’ve probably noticed similar signs in your own washer but haven’t given them much thought.

The truth is, your washing machine harbors at least 19 hidden spots where toxic mold can thrive, even if you’re diligent about regular cleaning.

While some areas are obvious, others lurk in places you’d never think to check – and one particular spot (#13) could be putting your family’s health at risk right now.

Let’s explore these danger zones before it’s too late.

Behind the Door Seal

Many front-loading washing machines accumulate debris, mold, and mildew behind their rubber door seals.

You’ll need to regularly inspect and clean this area to prevent toxic growth that can contaminate your laundry and release harmful spores into your home’s air.

Pull back the rubber gasket and you’ll likely discover black spots, soap scum, hair, and trapped moisture – perfect conditions for mold colonization.

Don’t let manufacturers’ maintenance schedules dictate your cleaning routine.

Instead, take control by wiping this area dry after each wash cycle and conducting a thorough cleaning every two weeks using a mixture of white vinegar and water or hydrogen peroxide.

For stubborn mold, use a specialized washing machine cleaner containing enzymes.

Remember to leave your washer door open between cycles to promote airflow and prevent moisture buildup.

Detergent Dispenser Drawer

While most users diligently add detergent to their dispensers, they don’t realize that these compartments harbor significant bacterial growth and limescale buildup.

Over time, detergent residue combines with moisture to create a perfect environment for mold and mildew to thrive.

You’ll need to remove the drawer completely – most models allow this by pressing the release mechanism at the back.

Inspect the cavity where your drawer sits; you’ll likely find black spots and slimy residue in the corners and crevices.

Don’t ignore the siphon tubes and overflow channels, as they’re prime spots for contamination.

To prevent this issue, remove and clean your dispenser weekly using hot water and vinegar solution.

After each wash cycle, leave the drawer slightly open to promote airflow and prevent moisture accumulation.

Rubber Gasket Folds

The rubber door gasket, a critical seal in front-loading washers, contains deep folds that trap moisture, hair, and debris.

These dark, damp crevices become perfect breeding grounds for black mold and mildew, which can transfer onto your clothes and release harmful spores into your home’s air.

You’ll need to inspect your gasket’s folds weekly, wiping them thoroughly with a microfiber cloth to remove buildup.

Don’t forget to check behind the rubber seal where it meets the drum – this hidden area often harbors the worst contamination.

If you spot black spots or smell musty odors, immediately clean with a solution of equal parts white vinegar and water.

For stubborn mold, use a specialized washing machine cleaner containing sodium hypochlorite.

After each wash, leave your washer door open to allow complete drying of the gasket.

Under the Agitator

Moving from external seals to internal components, your washer’s agitator harbors hidden debris zones that often go overlooked during routine cleaning.

You’ll find the most problematic area underneath the central agitator column, where fabric fibers, detergent residue, and mineral deposits accumulate in the base mechanism.

To inspect this area, you’ll need to remove the agitator cap and lift the entire component.

Look for a snap-off cap or release button at the top – most models don’t require tools for removal.

Once you’ve exposed the base, you’ll likely discover a buildup of black or brown sludge, which indicates a mix of detergent residue and organic matter.

This contamination can transfer onto your clothes and compromise your washer’s mechanical performance if left unchecked.

Drain Pump Filter

Accessing your washer’s drain pump filter reveals one of the most problematic collection points for debris and foreign objects.

You’ll find this essential component typically located behind a small door at the front bottom of your machine, though locations vary by model.

When left unchecked, this filter becomes a prime spot for mold growth and system blockages.

To inspect your drain pump filter, you’ll need to place towels beneath the access panel, as trapped water will likely spill out.

Unscrew the filter counter-clockwise, removing accumulated lint, coins, buttons, and other debris that’s collected over time.

Don’t forget to check the filter housing cavity itself – it’s often overlooked but can harbor significant mold growth.

Clean both the filter and housing with white vinegar solution before reinstalling to prevent future contamination.

Door Hinge Area

Hidden within your washer’s door hinge area lies a complex set of moisture-trapping crevices where mold and mildew thrive unchecked.

This critical junction point collects water, detergent residue, and fabric particles during each wash cycle, creating an ideal environment for toxic growth.

You’ll need to inspect both the upper and lower hinge mechanisms, paying special attention to the rubber seals and metal-to-plastic connection points.

Using a thin microfiber cloth or cotton swab, clean these areas thoroughly after every 30 wash cycles.

Don’t forget to check the hinge pin housing, where condensation often accumulates unnoticed.

If you spot black or green spots forming, immediately sanitize with a mixture of white vinegar and water (1:1 ratio).

Left untreated, hinge area mold can spread to your clothes and compromise your machine’s door seal integrity.

Water Inlet Filters

While the door hinge harbors visible threats, your washing machine’s water inlet filters serve as the first line of defense against microscopic contaminants.

Located where your water supply hoses connect to the machine, these mesh screens trap sediment, calcium deposits, and rust particles before they enter your washer.

You’ll need to check these filters every three months, as they’re prone to clogging with mineral buildup and debris.

If you notice reduced water flow, longer fill times, or error codes, your inlet filters likely need cleaning.

To access them, disconnect power, shut off water valves, and unscrew the hoses.

Remove the filters using needle-nose pliers, soak them in vinegar solution for 30 minutes, then scrub with a small brush.

Don’t skip this maintenance – clogged filters can damage your machine’s water valves and control board.

Between Drum and Tub

The narrow space between your washer’s inner drum and outer tub accumulates some of the most problematic debris over time.

Hair, lint, detergent residue, and mineral deposits collect in this hidden gap, creating an ideal environment for mold and bacteria growth.

You’ll need a flashlight to inspect this area properly.

If you notice black spots or a musty odor coming from your washer, it’s likely there’s buildup in this space.

You can’t clean this area through normal maintenance, as it requires partial disassembly of the machine.

Don’t ignore this spot – accumulated grime here can transfer onto your clothes and cause mechanical issues with the drum’s rotation.

Consider hiring a professional technician for a thorough cleaning if you suspect significant buildup, or tackle it yourself using a specialized cleaning wand designed for this purpose.

Soap Residue Collection Points

Soap residue presents another major challenge beyond the drum-tub gap, forming stubborn deposits in multiple locations throughout your washing machine.

You’ll find these accumulations primarily in the detergent drawer, dispenser channels, and along the door seal’s rubber gasket.

Check your machine’s detergent drawer for a removable insert – it’s likely harboring thick, slimy buildup in its corners and drainage holes.

The channels that carry soap from the drawer to the drum often develop blockages you can’t see.

Don’t overlook the rubber door seal’s folds, where residue combines with mineral deposits to create a paste-like substance that traps debris and moisture.

These collection points require monthly cleaning with vinegar or specialized washing machine cleaner to prevent mold growth and maintain ideal water flow.

Fabric Softener Compartment

Neglect of your fabric softener compartment often leads to severe buildup and drainage problems.

The compartment’s narrow channels and tight corners create perfect conditions for mold growth, especially when residual softener combines with moisture and stagnant air.

You’ll need to inspect the removable parts monthly. Check for black or green spots, which indicate toxic mold formation.

If you notice a musty smell or slimy residue, your compartment requires immediate cleaning.

Remove the drawer completely, and soak it in hot water mixed with vinegar for 30 minutes.

Don’t forget to examine the cavity behind the drawer – it’s a commonly overlooked spot where mold thrives.

Use a small brush to scrub the cavity walls and spray ports.

Clear any blockages in the siphon tubes to guarantee proper softener distribution during future wash cycles.

Main Drain Hose

While most users focus on visible washing machine components, your main drain hose can accumulate significant debris and mineral deposits over time.

This critical component transports wastewater from your machine to your home’s drainage system, making it susceptible to blockages and contamination.

You’ll need to check the hose’s connection points monthly for signs of buildup, mold, or deterioration.

Simply detach the hose from both ends and inspect its interior using a flashlight.

If you notice black residue, calcium deposits, or a musty odor, it’s time for immediate cleaning.

Run a mixture of hot water and white vinegar through the hose, followed by a stiff brush designed for drain cleaning.

Don’t forget to examine the hose for cracks or weak spots that could lead to leaks, especially near the bends where stress occurs most frequently.

Control Panel Edges

The small gaps around your washing machine’s control panel harbor a surprising amount of detergent residue and moisture.

These narrow crevices collect powder detergent, fabric softener droplets, and water splashes during each wash cycle, creating an ideal environment for mold growth.

You’ll need a thin cleaning tool, like a microfiber cloth wrapped around a credit card, to access these tight spaces.

Dip your tool in a solution of equal parts white vinegar and water, then carefully run it along the panel’s edges to dissolve built-up residue.

Don’t forget to check beneath the buttons and dials, where moisture often accumulates unnoticed.

Make this inspection part of your monthly maintenance routine.

If you spot black or green spots forming, immediately clean the area with a hydrogen peroxide solution to prevent mold from spreading behind the panel.

Bleach Dispenser Channel

Inside modern washing machines, a dedicated channel guides bleach from the dispenser to the drum, frequently accumulating calcium deposits and bleach residue that can restrict flow.

If you’ve noticed your bleach isn’t dispersing properly, this channel’s likely the culprit.

You’ll need to check this passageway monthly, as blockages can cause bleach to back up or dispense unevenly, potentially damaging your clothes.

To clean it, disconnect power, locate the bleach dispenser opening, and insert a pipe cleaner or thin brush.

You’ll often find white crusty buildup – that’s calcium combining with bleach residue.

Don’t ignore this maintenance task, as blocked channels can lead to mold growth and reduced cleaning effectiveness.

For stubborn deposits, you can use white vinegar to dissolve the buildup, followed by a thorough rinse with hot water.

Air Vent System

Moving from chemical flow paths to airflow mechanics, your washing machine’s air vent system functions as a pressure equalizer and moisture release network.

During operation, these vents prevent vacuum formation while releasing excess humidity and maintaining ideal drum pressure.

Without proper maintenance, they’ll become breeding grounds for black mold.

You’ll find the primary vent ports along the upper rim of your washer’s drum, often concealed beneath the top panel or door gasket.

Check these vents monthly for blockages and biofilm buildup.

If you notice musty odors or excessive condensation, your vents likely need immediate attention.

Clean them using a thin brush and a mixture of white vinegar and water, ensuring you’ve reached deep into the channels where spores typically colonize.

Don’t forget to dry the vents thoroughly after cleaning.

Door Lock Mechanism

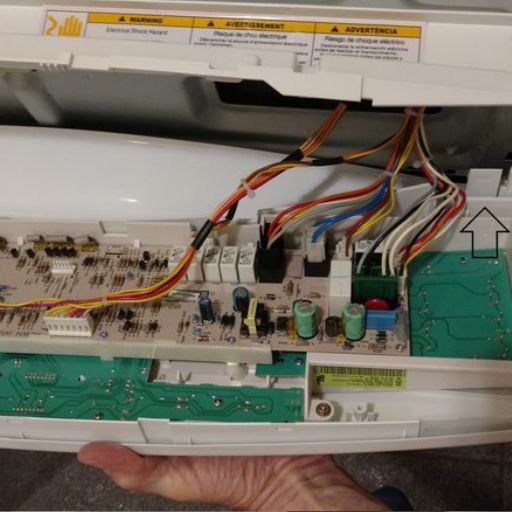

Your washer’s door lock mechanism serves as a critical safety interlock system, integrating both mechanical and electrical components to prevent mid-cycle access.

Behind the visible latch, you’ll find a complex network of springs, switches, and moisture-prone areas where mold can flourish undetected.

To inspect this area, you’ll need to remove the lock assembly’s outer housing.

Look for black or greenish spots around the rubber gasket and metal components.

Pay special attention to the electrical contacts, as corrosion here can compromise both safety and functionality.

If you notice a musty odor or resistance when engaging the lock, it’s time for a deep clean.

You can access this area by disconnecting power, removing two to three screws, and gently pulling the mechanism forward.

Don’t forget to check the striker plate on the door itself.

Water Supply Hose Connections

Hidden behind the access panel, water supply hose connections represent critical junction points where external plumbing meets your washing machine’s internal water distribution system.

You’ll find both hot and cold water connections, typically secured with rubber washers and metal fittings that can deteriorate over time.

Check these connections monthly for signs of corrosion, mineral buildup, or rubber degradation.

If you notice green or white crusty deposits, black mold spots, or moisture beading around the fittings, you’re at risk of a catastrophic leak.

Don’t wait for disaster – inspect the rubber seals for cracks, and verify the metal threads aren’t crossed or stripped.

You’ll want to replace your supply hoses every 3-5 years, even if they look fine, as internal deterioration isn’t always visible from the outside.

Bottom Panel Corners

While water connections sit at the back of your machine, the bottom panel corners often harbor their own set of maintenance concerns.

These recessed areas collect debris, lint, and moisture, creating perfect conditions for mold growth.

You’ll find these corners where the front panel meets the base, typically hidden behind the kick plate.

To inspect these spots, you’ll need a flashlight and a flat-head screwdriver to remove the kick plate.

Look for black or greenish spots, which indicate mold formation.

Don’t ignore white residue either – it’s often mineral buildup that traps moisture.

Clean these corners quarterly using a mixture of vinegar and water, ensuring you’re reaching deep into the crevices with a thin brush.

If you spot rust, address it immediately as it suggests ongoing moisture problems that’ll compromise your machine’s structural integrity.

Drum Paddle Gaps

Deep within the washing machine drum, the paddle gaps pose significant maintenance challenges due to their narrow spacing and frequent exposure to detergent residue.

These crevices between the agitator paddles and drum wall collect lint, soap scum, and moisture, creating perfect conditions for mold growth.

You’ll need to inspect these gaps monthly using a flashlight, paying special attention to the dark spaces where the paddles meet the drum’s surface.

If you spot black or green patches, they’re likely toxic mold colonies that can contaminate your laundry.

Use a thin cleaning brush or cotton swab dipped in white vinegar to scrub these areas thoroughly.

Don’t forget to run an empty hot water cycle afterward to flush out any remaining debris.

For stubborn buildup, you can remove the paddle assembly following your machine’s maintenance guide.

Temperature Sensor Housing

The temperature sensor housing, often adjacent to the drum assembly, represents another problematic area for maintenance oversight.

This critical component monitors water temperature but can accumulate soap residue and mineral deposits in its protective casing.

You’ll find it’s particularly susceptible to biofilm formation where the sensor meets the drum wall.

To access this area, you’ll need to remove the drum’s front panel.

Look for a small plastic or metal housing with wiring connected to it.

Don’t overlook the rubber gasket surrounding the sensor, as it’s a prime spot for black mold growth.

You can clean this area using a vinegar-water solution and a narrow brush, making sure to reach behind the housing where moisture tends to collect.

Regular inspection of this spot helps prevent inaccurate temperature readings and potential washing performance issues.

FAQs

Can Washing Machine Mold Affect My Family’s Respiratory Health Over Time?

Yes, mold in your washing machine can trigger respiratory issues, allergies, and chronic inflammation. You’ll want to monitor symptoms like coughing, wheezing, and nasal congestion, especially in children and immunocompromised family members.

What Temperature Kills Mold Spores During the Washing Machine Cleaning Cycle?

You’ll need to run your washer at 140°F (60°C) or higher to effectively kill mold spores. A 90-minute hot cycle with vinegar or specialized cleaner guarantees maximum spore elimination in your machine’s components.

How Often Should Professional Maintenance Be Done to Prevent Mold Buildup?

Want ideal protection? You’ll need professional maintenance every 12-18 months to prevent mold buildup. Don’t wait longer, as technicians can deep-clean critical components and inspect seals that aren’t accessible during routine cleaning.

Which Natural Cleaning Solutions Work Best for Removing Mold Stains?

You’ll find white vinegar, baking soda, and tea tree oil effectively eliminate mold stains. Mix vinegar with water (1:1 ratio), spray directly, or create a paste with baking soda for stubborn areas. Let it sit 30 minutes.

Does the Brand or Model of Washing Machine Affect Mold Growth?

Yes, your machine’s design affects mold growth. Front-loaders are more susceptible due to door seal designs, while top-loaders generally have better ventilation. High-efficiency models need extra maintenance to prevent moisture accumulation.

Final Thoughts

You’ll need to inspect these nine critical areas regularly to prevent toxic mold growth that can compromise both your machine’s functionality and your respiratory health.

Consider the case of the Johnson family in Denver, who discovered black mold colonization in their drain pump filter (#13) after experiencing unexplained allergic symptoms.

Their $1,200 front-loading washer required professional remediation due to delayed maintenance, which could’ve been prevented through monthly inspections.